Subsequent on the cleaning system, tools can be subjected to sterilization or sanitization strategies in which these kinds of tools is employed for sterile processing, or for nonsterile processing the place the items may perhaps aid microbial expansion. Whilst this sort of sterilization or sanitization processes are outside of the scope of this guideline, it's important to notice that control of the bioburden by way of suitable cleaning and storage of equipment is crucial to ensure that subsequent sterilization or sanitization strategies achieve the necessary assurance of sterility.

The natural environment should be sampled throughout regular functions to allow for the collection of significant data. Microbial sampling must occur when components are while in the area, processing actions are ongoing, and a complete enhance of functioning staff is on internet site.

Action Stages—Microbiological levels inside the managed ecosystem, specified in the common working techniques, which when exceeded must set off an investigation and a corrective motion depending on the investigation.

Airflow Quantity Measurement: This take a look at actions the total quantity of air supplied or removed from the cleanroom to confirm that it fulfills the designed air exchange prices, which can be important for retaining the cleanroom’s cleanliness level.

air supplied towards the cleanroom is of sufficient quantity to dilute or take out contamination generated in the cleanroom,

Timetable repairs and upkeep through off-hrs to minimize disruptions and accomplish them in isolation to stop contamination.

FDA expects a final validation report which can be accredited by management and which states whether or not the cleaning procedure is legitimate. The data should aid a summary that residues are diminished to an "acceptable stage."

They're also obtainable in Prepared-to-use variety. When disinfectants or antibiotics are Employed in the controlled area, consideration ought to be supplied to working with media with correct inactivating brokers.

Equipment like circuit breakers, switches, contactors and so forth., that may induce arcing and sparking shall be enclosed in explosion evidence housings. Confer with Article a hundred with the NEC for definitions of explosion evidence gear.

The widespread utilization of isolator methods for sterility screening has demonstrated that elimination click here of personnel does reduce contamination in aseptic managing.

Examine and Examine the level of testing as well as the retest benefits considering the fact that screening till clean is a concept used by some manufacturers. They test, resample, and retest gear or methods until an "appropriate" residue level is attained. For the method or gear having a validated cleaning procedure, this exercise of resampling really should check here not be utilized and is suitable only in exceptional cases.

Usually, as soon as the validation establishes the success of the barrier method, the frequency of sampling to monitor the microbiological status from the aseptic processing area could be reduced, in comparison with the frequency of sampling of classical aseptic processing techniques.

Dangerous simply because ignitable fibers or flyings are current (or could be existing) in quantities sufficient to create explosive or ignitable mixtures.

The first cause for qualifying cleanrooms is always to validate that the House is able to maintaining the demanded levels of contamination control.

Hailie Jade Scott Mathers Then & Now!

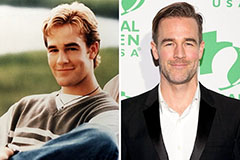

Hailie Jade Scott Mathers Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now! Megyn Kelly Then & Now!

Megyn Kelly Then & Now! Mike Smith Then & Now!

Mike Smith Then & Now!